Previously, we have discussed the pros and cons of being an electrical engineer. This time, we are going to look at the tools our electrical engineer uses to do soldering.

What Is Soldering?

Soldering is the process of melting solder by using heat to join two or more electronic parts to create a permanent connection. Once the solder has cooled and hardened, it will become a strong electrical joint..

What Are The Tools Used In Soldering?

If you are an electrical engineering student or just someone interested in electronics, chances are you are going to solder a lot. Generally speaking, there are only two items that you need to do simple soldering, which is soldering iron and soldering wire.

Soldering Iron

Soldering iron is a hand-held tool that produces heat in order to melt solder around electrical connections. There are various uses of a soldering iron, such as to fix, build, assemble or disassemble items, and many others. However, the primary use of a soldering iron is for soldering and desoldering.

Our team uses electric-powered pen soldering iron. By using an electric soldering iron, temperature consistency can be maintained. The soldering iron also comes with an interchangeable soldering tip and can come in various shapes and sizes, each designed for a specific purpose. The current tip is a conical tip used for precision soldering due to its finer tip.

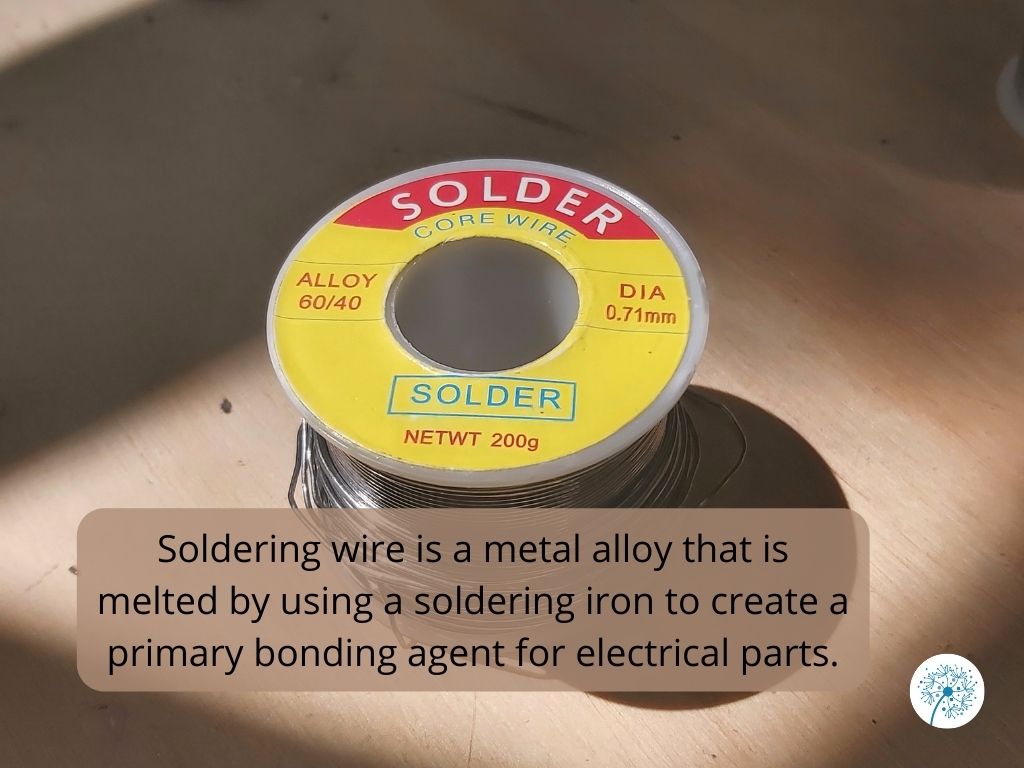

Soldering Wire

Soldering wire is a metal alloy that is melted by using a soldering iron to create a primary bonding agent for electrical parts. It comes in 2 variations, leaded solder, and lead-free solder. Lead solder is typically less popular due to health concerns. Due to the nature of the precision soldering, our team uses a 0.032″ diameter lead-free solder.

What Are The Soldering Tools That Will Make Your Life Easier?

Although soldering can be done by using only a soldering iron and a solder, proper soldering items are necessary when you start doing more complex projects.

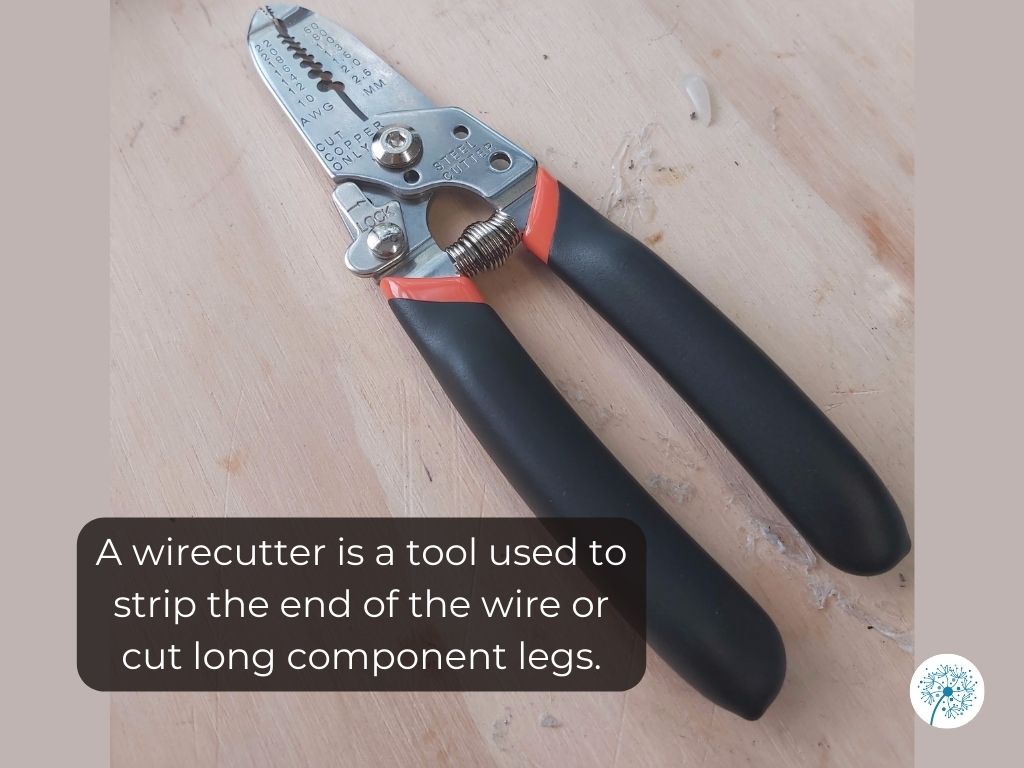

Wirecutter

Wirecutter is a tool used to strip the end of the wire or cut long component legs. Of course, you can use a scissor to cut wires. However, a wire cutter ensures that you will not hurt yourself while trying to do so.

Soldering Iron Stand

Soldering irons can reach a really high temperature. A soldering iron stand is a tool to hold your hot soldering iron safely in between soldering. It helps prevent the tip of the soldering iron from coming in contact with flammable materials or causing accidental injury to your hand.

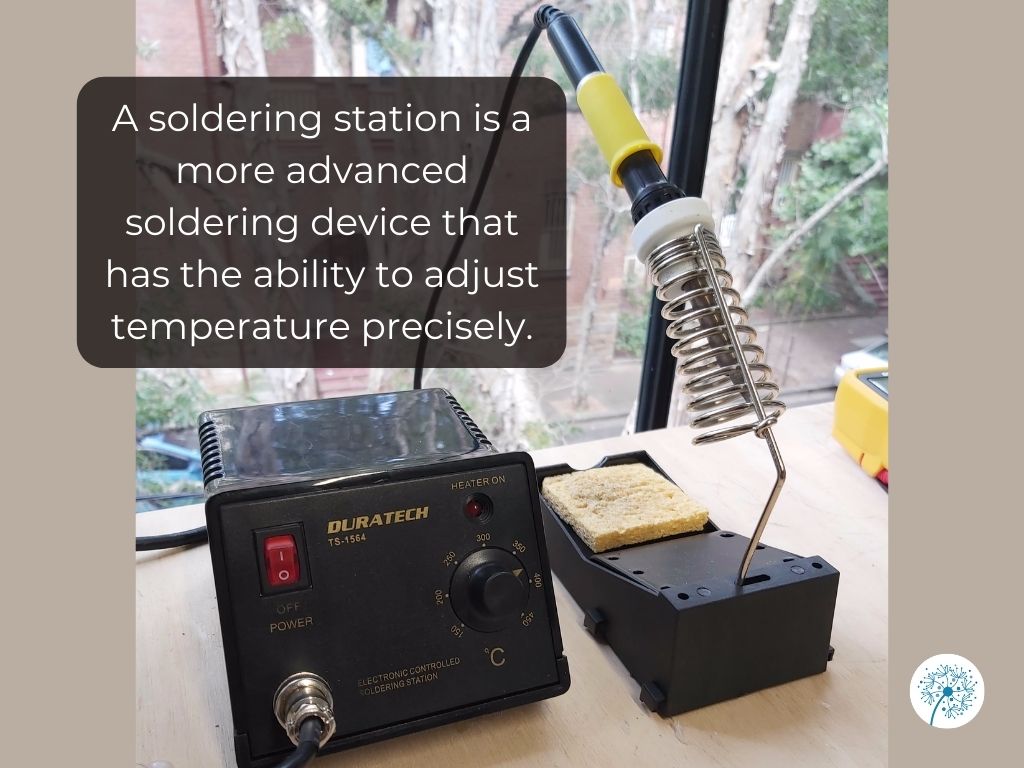

Soldering Station

Soldering station is a more advanced soldering device that has the ability to adjust temperature precisely. In addition, it can also create a safer workspace as some include advanced temperature sensors, alert settings, and even password protection for safety.

Our team uses a 48W Temperature Controlled Soldering Station that features an accurate analogue temperature adjustment, ceramic element, and a lightweight pencil for precision soldering.

Soldering Tip

A soldering tip is the end of a soldering iron that is mostly interchangeable according to your need. Soldering tips can come in various shapes and sizes, each designed for a specific purpose. The current tip we use is a conical tip used for precision soldering due to its finer tip.

Wet or Brass Sponge

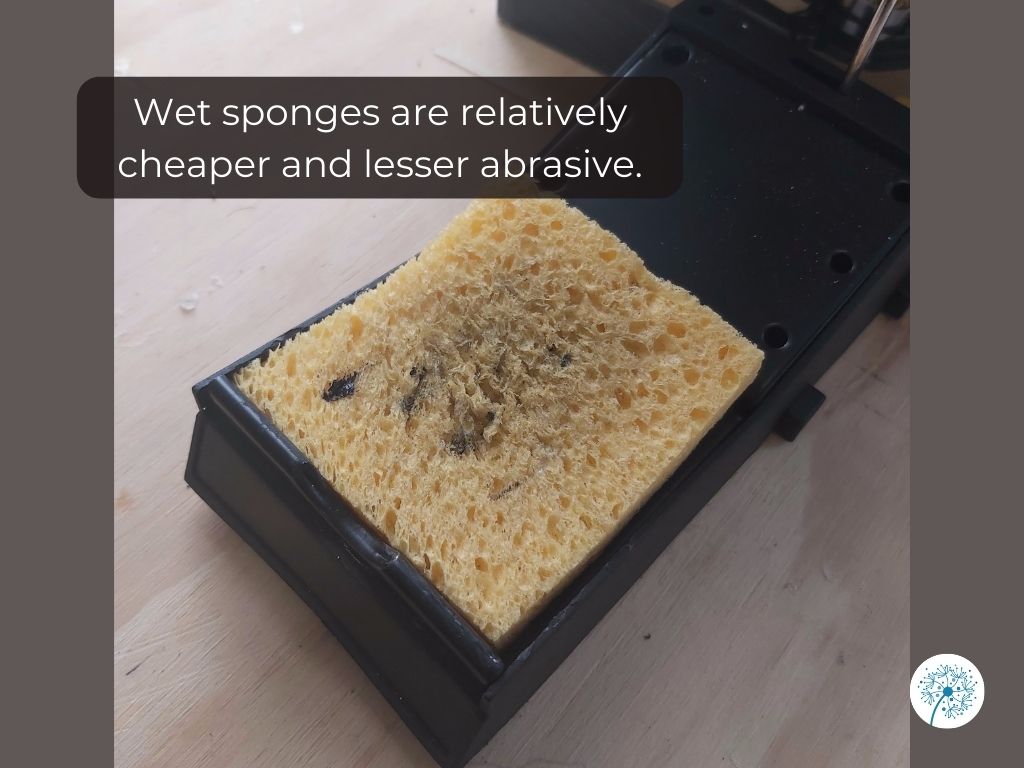

A sponge is used to help keep the soldering iron tip clean. There are two types of sponges used to clean the soldering iron tip; a wet sponge or a brass sponge.

Prior to starting the soldering project, it’s important to reduce the debris collected on the tip transferring over to your next projects. Wet sponges are relatively cheaper and lesser abrasive. Meanwhile, brass sponges are better for “harder to remove” debris and are lesser susceptible to thermal shock.

Helping Hand or Third Hand

The helping hand is a device that contains 3 alligators clips connected to a shaft with a magnifying glass/light attachment. These clips assist in keeping the electronics completely steady during the soldering process.

Soldering Flux and Flux Pen

Soldering flux and the flux pen assist in preparing the metal surfaces by cleaning and removing impurities before the soldering process. After the soldering process, Rosin based flux will require cleaning with specific chemical solvents. In contrast, a no-clean flux pen, as the name suggests, will require little to no cleaning. However, residual flux can reduce the effectiveness of coatings, so it is recommended that some cleaning is involved.

How Can You Do Soldering Safely?

Knowing the tools for soldering is not enough. Safety measurements are also required to ensure that you and the people around you are safe while soldering. There are several things that you need to do to ensure safety.