It was a gruelling process, getting through the testing for the Waratah Seed Mission. Here is a story of many fails, but a final, big win!

Inception And Inspiration

Every great project begins with a spark of inspiration, and our CubeSat payload project was no exception. It all started when our CEO received word of a cheap launch opportunity 2 years ago.

What could we learn, discover, and achieve with the power of a small, versatile payload?

Read our blog post about that win here.

As we brainstormed, we discovered that CubeSats provided the perfect canvas for our aspirations.

With their compact size, affordability, and rapid development cycle, we saw an opportunity to venture into uncharted territories of space research.

Making Friends...

We had been lucky enough to make some really good contacts within the Australian space industry. Down under, after is, is a pretty small place.

In conjunction with our university partners, we developed preliminary designs to validate using biodegradable composite materials called Amplitex for spacecraft development.

The mission would conduct a series of cyclic deformation tests in orbit to determine the structural integrity of Amplitex to survive the space environment.

In short, the idea was to build a satellite that could test the ability of a biodegradable material to survive the harsh environment of space.

If demonstrated successfully, this would lead to significant opportunities in building and designing limited lifespan small satellites.

Why Amplitex?

Well, the ESA had previously tested Amplitex so it was a pretty good candidate, but more research was required to understand the material further in terms of radiation and durability.

Designing And Building A CubeSat

Designing a CubeSat payload is a multifaceted challenge. It's about more than just squeezing as many sensors and instruments as possible into a tiny frame. Instead, it's about carefully selecting the right tools for the mission.

We spent countless hours considering the objectives of our mission and the specific instruments needed to accomplish them.

We had to balance scientific goals with the limitations of CubeSat technology, all while ensuring our material samples were robust enough to withstand the harsh conditions of space.

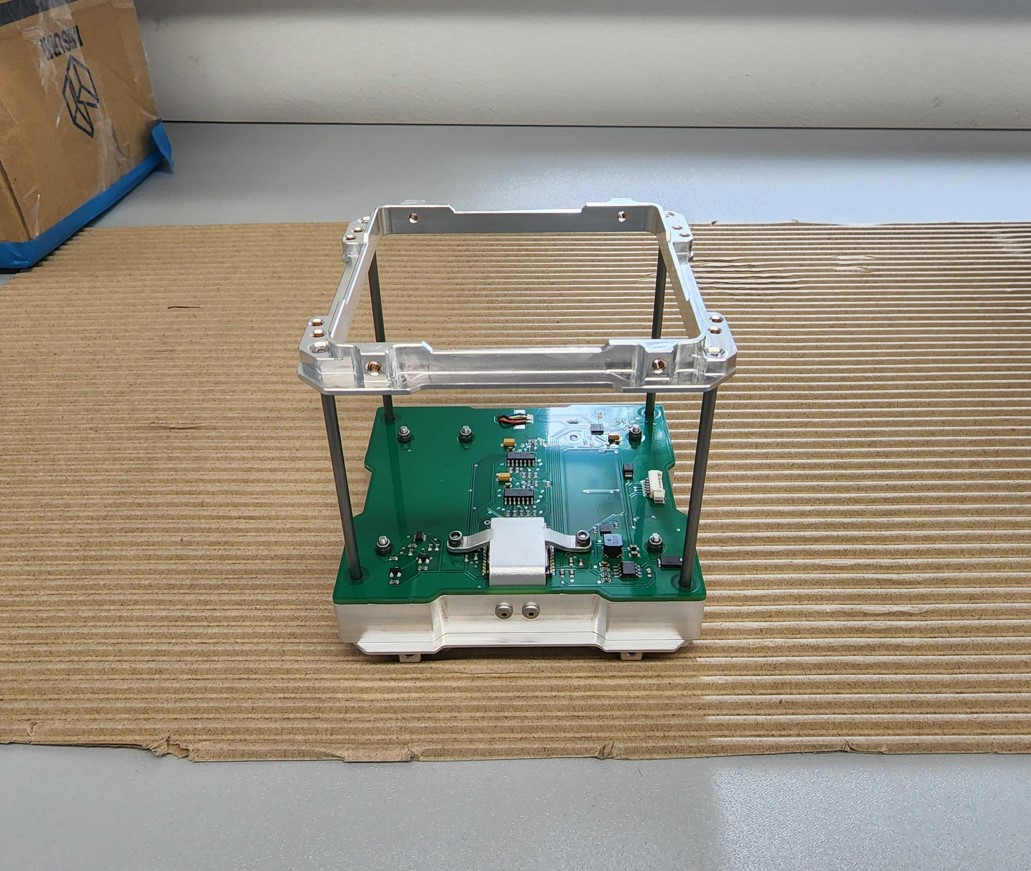

Once the design was finalised, the real work began. Building a CubeSat payload is a meticulous process that demands a blend of technical expertise, patience, and teamwork.

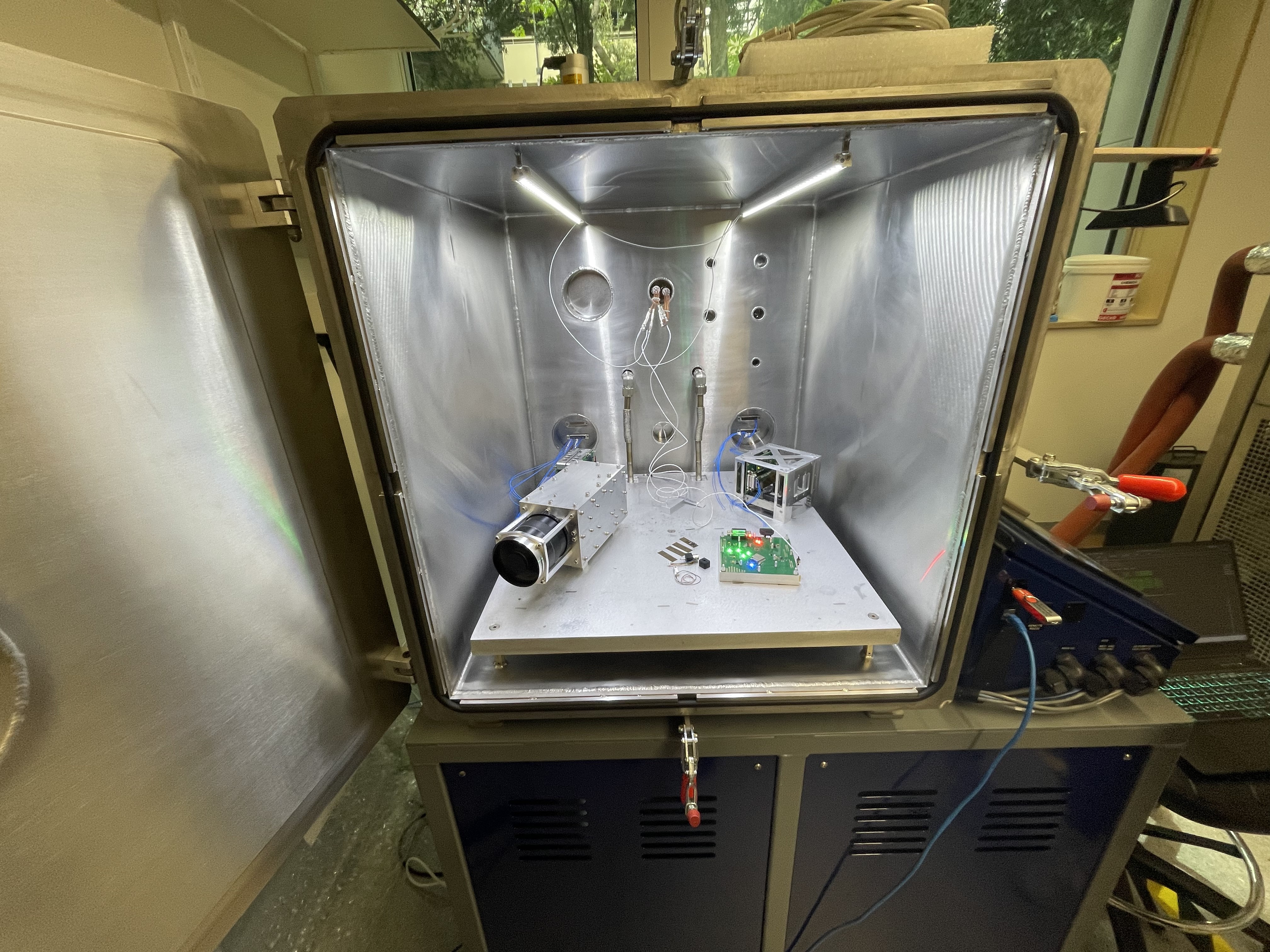

We procured the necessary components through our trusted suppliers, assembled the payload in-house, and rigorously tested it to ensure every piece was in perfect working order.

One of the most challenging aspects was the size constraint and supply chain obstructions.

CubeSats are compact, and every millimetre counts. Precision was essential, and we learned that patience truly pays off when assembling these miniature marvels.

As the payload neared completion, the excitement in our team reached new heights. But before we could launch our creation into the cosmos, it had to pass rigorous tests.

CubeSats face extreme temperatures, radiation, and the vacuum of space, so it's essential to prepare them for these harsh conditions.

Our testing phase was both nerve-wracking and exhilarating.

We watched as our payload endured simulations of the space environment, making sure it could handle our space environment requirements.

Types of Testing

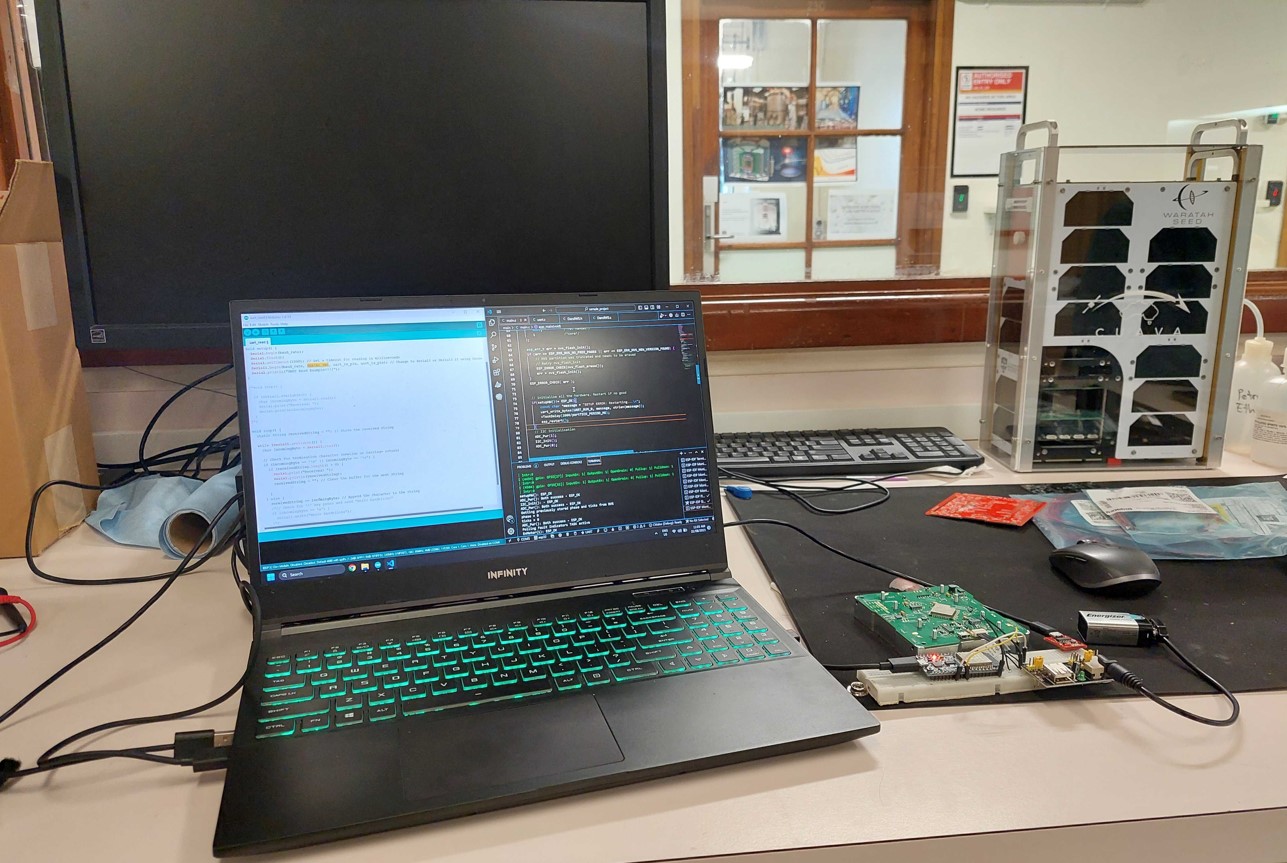

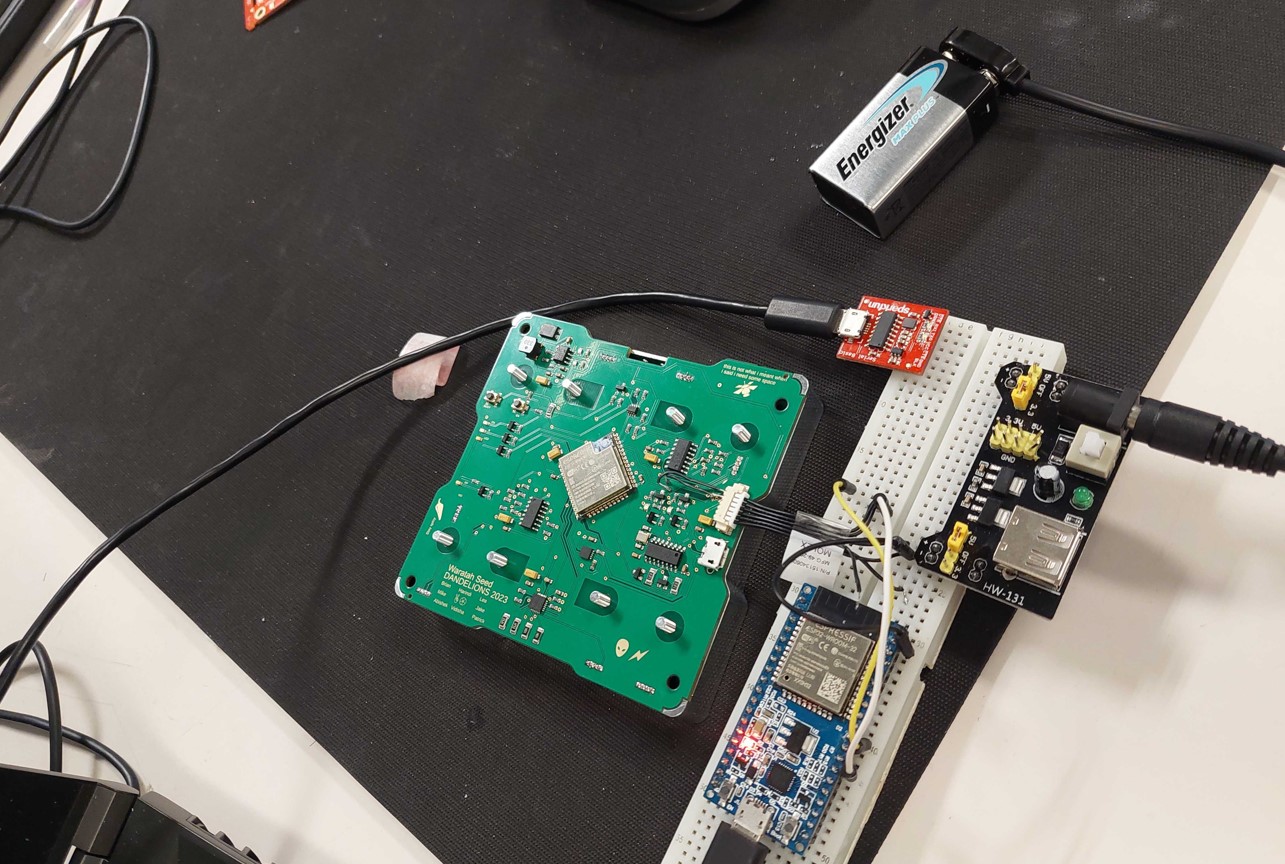

Ensuring that our flight software was error-free was critical. We ran simulations and tested every line of code, putting our algorithms through their paces. The code had to be robust, adaptable, and capable of handling unexpected situations that could arise during the mission.

While we diligently designed every aspect of our CubeSat payload, the real world often throws unexpected challenges our way. Debugging became a daily ritual as we encountered minor hiccups and unforeseen glitches in power.

But with patience and persistence, we clarified each issue, taking one step closer to our launch. Sometimes, even the most carefully crafted components needed a little fine-tuning. We found ourselves reworking the PCB, striving for perfection.

It was a humbling reminder that space is an unforgiving environment, and our payload needed to be flawless to endure it.

As we watched our payload being integrated into the satellite, a mix of emotions washed over us. There was a sense of pride and accomplishment, knowing that our creation was one step closer to fulfilling its mission.

At the same time, there was a hint of bittersweet nostalgia as we let go of something that had become a part of us.

Bound For Space!

The CubeSat now belonged to a larger mission, guided by a team at Waratah Seed who would ensure its safe journey into space and its successful operation once it got there. It was a moment that underscored the collaborative nature of space exploration.